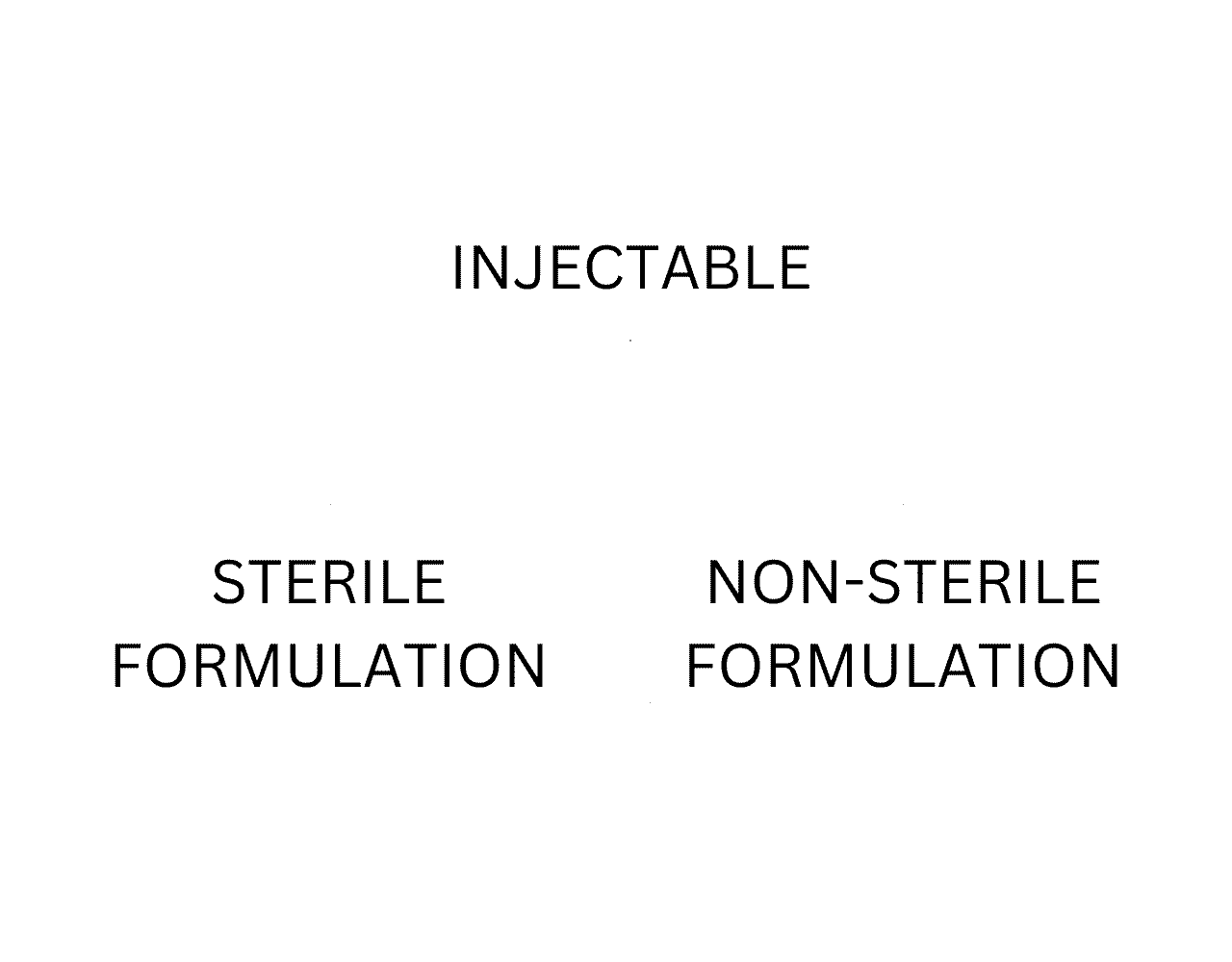

Non-Sterile Process

At BioAspire, we specialize in parenteral dosage forms, including sterile injectable drugs. We manufacture Vessels as per the cGMP guidelines, which means meeting stringent FDA guidelines for quality and safety. Injectable manufacturing demands strict sterility, non-pyrogenicity and data traceability to prevent severe harm or life-threatening health risks to patients. Our team understands these demands and has the experience and equipment to ensure that end-products are unadulterated and free of all pathogens.

Our manufacturing facility and Testing facility has requisite norms for the utmost importance for the sterility and data traceability. We are equipped to provide sterile Vessels for stable sterile injectable drugs, as well as aseptic manufacturing for biologics and other sterile injectables that are not suitable for terminal sterilization.

- Master /central CIP station and local recirculation

- One tank/two tank system with/without dosing of cleaning agents

- One tank/two tank system with/without heat exchanger

- One tank/two tank system with/without jacket

- Mobile CIP recirculation trolley with /without preparation vessel

- Mobile CIP recirculation trolley with /without HEX

- Mobile CIP recirculation trolley with /without dosing of cleaning agents

- Tankless CIP recirculation Trolley

- Two tank systems with two pumps for supply & return of CIP

- Two pump systems with independent loops of cleaning agents and local recirculation

- Mobile One Tank System with Local Recirculation

- Smart design of a combo unit of CIP & SIP in one system skid.

- Complete automated CIP: Most reliable, controlled & consistent performance without any intervention from operator.

- Semi-automated: Reliable, consistent in performance but requires certain level of manual intervention.

- Complete manual option: Not reliable, not consistent as it is directly depending on the skill set of the operator.