Menu

CIP & SIP

Never allow contamination to occur in any process or product during batch-to-batch processing. Our systems are subjected to residue/trace removal and cleaning from completed batches, as well as ensuring that the manufacturing process vessels, auxiliary systems, and interconnecting process piping are free of cross contamination.

We offer all possible CIP solutions to the client in our effort to assist end users with customised options of CIP designing with BAPS’s value added process inputs to suit their process, layouts, and budget requirements. It gives the client complete freedom to choose the best solution.

- Master /central CIP station and local recirculation

- One tank/two tank system with/without dosing of cleaning agents

- One tank/two tank system with/without heat exchanger

- One tank/two tank system with/without jacket

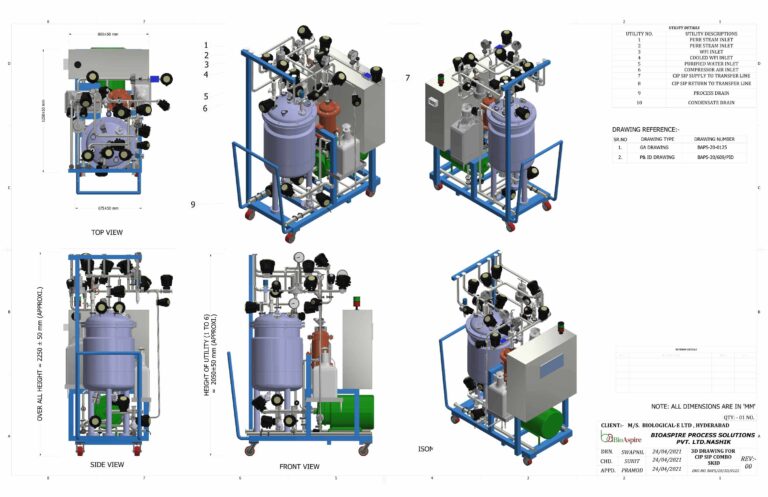

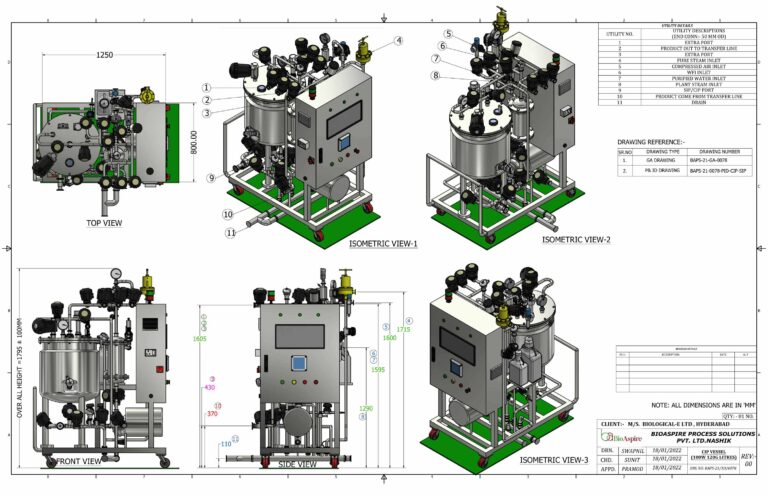

- Mobile CIP recirculation trolley with /without preparation vessel

- Mobile CIP recirculation trolley with /without HEX

- Mobile CIP recirculation trolley with /without dosing of cleaning agents

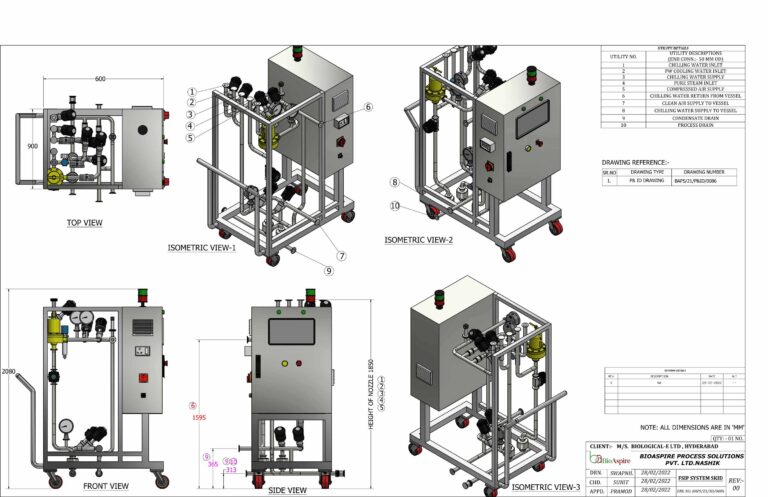

- Tankless CIP recirculation Trolley

- Two tank systems with two pumps for supply & return of CIP

- Two pump systems with independent loops of cleaning agents and local recirculation

- Mobile One Tank System with Local Recirculation

- Smart design of a combo unit of CIP & SIP in one system skid.

- Complete automated CIP: Most reliable, controlled & consistent performance without any intervention from operator.

- Semi-automated: Reliable, consistent in performance but requires certain level of manual intervention.

- Complete manual option: Not reliable, not consistent as it is directly depending on the skill set of the operator.